Über uns

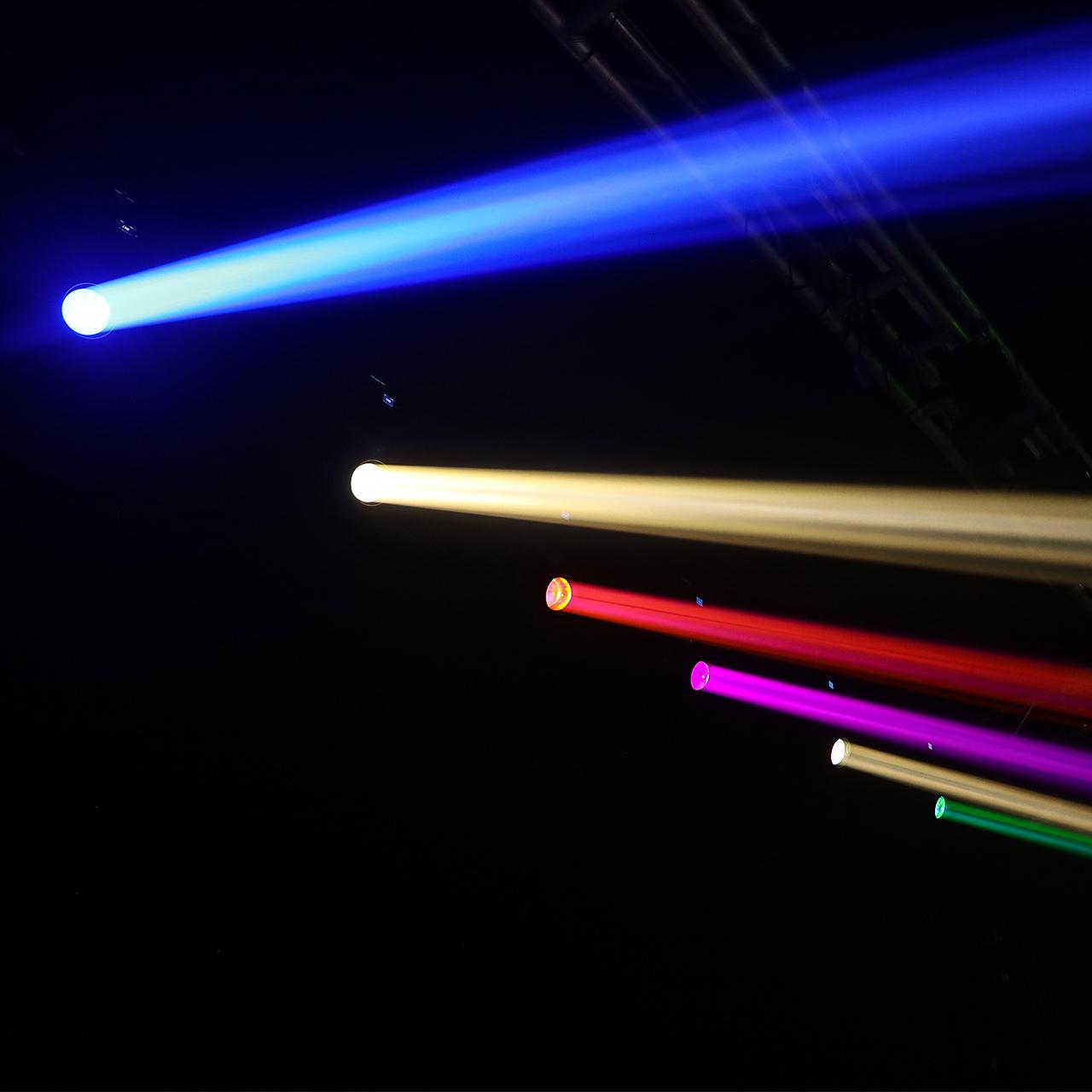

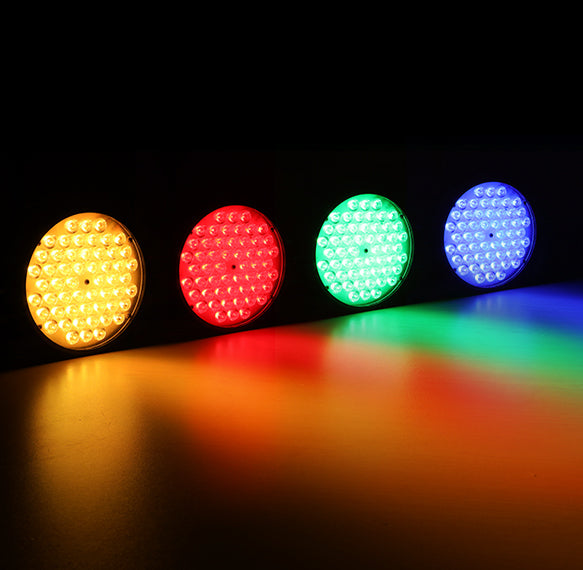

We are a company dedicated to making high-quality stage lighting products accessible to everyone, offering professional lighting solutions to customers worldwide. Since our establishment in 2003, we have been deeply rooted in the stage lighting industry, leveraging over 20 years of experience to drive innovation and industry progress.

All our products are independently researched and developed, with more than 10 patents to showcase our excellence in technological innovation and quality control. Our globally registered brands—Big Dipper, BETOPPER, and Seven Stars—have earned the trust and recognition of customers around the world.

Committed to our core value of “providing professional stage lighting that everyone can afford and rely on,” we deliver the best prices along with exceptional after-sales service. From technical support to comprehensive customer care, we ensure a seamless experience and peace of mind for all our clients.

Looking ahead, we will continue to focus on developing high-quality, professional lighting products. Through innovation and dedicated service, we aim to create endless possibilities for stage artistry and the entertainment industry.

Why Choose Us?

We are committed to making high-quality stage lighting accessible to everyone!

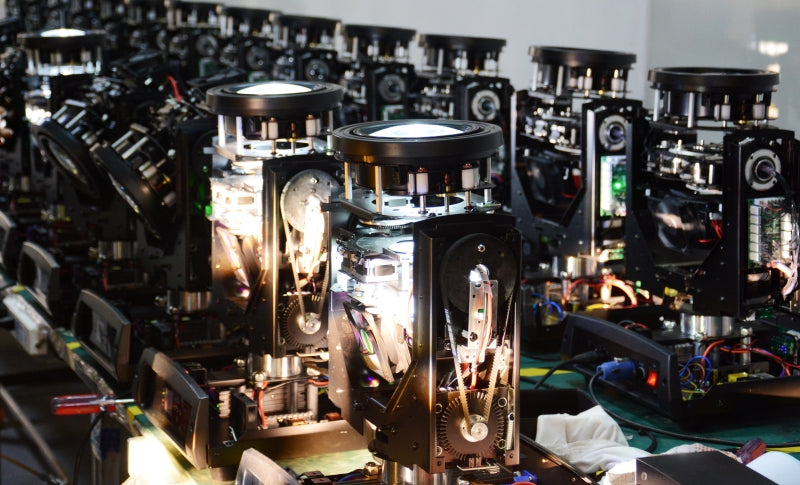

In-house manufacturing excellence refers to the ability of a company to optimize its internal production processes to achieve superior quality, efficiency, and cost-effectiveness in creating products. When it comes to lighting equipment, achieving in-house manufacturing excellence can lead to numerous competitive advantages, including better control over product quality, faster innovation cycles, reduced lead times, and enhanced customization capabilities. Here are key strategies for achieving **in-house manufacturing excellence** in the production of lighting equipment: --- ### 1. **Investment in Advanced Technology** - **Automation & Robotics**: Implement automated machinery and robotics to streamline repetitive tasks, improve precision, and reduce human error. This is especially critical for assembling intricate components like LED chips or circuit boards. - **Smart Manufacturing (Industry 4.0)**: Utilize IoT-enabled devices, sensors, and data analytics to monitor production lines in real time. This allows for predictive maintenance, reduced downtime, and improved resource allocation. - **3D Printing/Additive Manufacturing**: Use additive manufacturing for prototyping or producing custom parts quickly and efficiently. --- ### 2. **Focus on Quality Control** - **Standardized Processes**: Establish standardized workflows that ensure consistency across all stages of production. - **Rigorous Testing Protocols**: Conduct comprehensive testing for electrical safety, thermal performance, light output, and durability before products leave the facility. - **Continuous Improvement (Kaizen)**: Foster a culture of continuous improvement where employees at every level contribute ideas for enhancing quality and efficiency. --- ### 3. **Skilled Workforce Development** - **Training Programs**: Provide ongoing training for staff to keep them updated on the latest technologies and best practices in lighting manufacturing. - **Cross-Functional Teams**: Encourage collaboration between engineering, design, and production teams to solve problems holistically and innovate more effectively. - **Retention Strategies**: Offer competitive compensation packages and career growth opportunities to retain top talent. --- ### 4. **Lean Manufacturing Principles** - **Waste Reduction**: Identify and eliminate waste in materials, energy consumption, and labor through lean methodologies such as Six Sigma or 5S. - **Just-in-Time Production**: Optimize inventory management by aligning raw material procurement with actual production needs, minimizing excess stock and storage costs. - **Value Stream Mapping**: Analyze the entire production process to identify bottlenecks and areas for improvement. --- ### 5. **Customization Capabilities** - **Flexible Manufacturing Systems (FMS)**: Design production lines that can easily adapt to different types of lighting fixtures, from residential lamps to industrial-grade floodlights. - **Customer-Centric Solutions**: Leverage in-house expertise to offer tailored solutions based on specific client requirements, such as unique form factors, color temperatures, or smart integration features. --- ### 6. **Sustainability Initiatives** - **Energy-Efficient Operations**: Transition to renewable energy sources and implement energy-saving measures within the factory. - **Eco-Friendly Materials**: Source sustainable materials and adopt recyclable packaging to minimize environmental impact. - **Circular Economy Practices**: Develop take-back programs for end-of-life products to recover valuable materials and reduce waste. --- ### 7. **Supply Chain Optimization** - **Vertical Integration**: Bring critical components of the supply chain in-house, such as LED chip fabrication or driver electronics assembly, to reduce dependency on external suppliers. - **Supplier Collaboration**: For non-core items, partner closely with trusted suppliers to ensure timely delivery and high-quality inputs. --- ### 8. **Research & Development (R&D)** - **Innovation Hub**: Create an R&D center focused on developing cutting-edge lighting technologies, such as tunable white lights, human-centric lighting, or advanced optics. - **Patent Portfolio**: Invest in intellectual property development to protect proprietary designs and technologies. - **Market Trends Alignment**: Stay ahead of industry trends by incorporating emerging technologies like AI-driven controls, Li-Fi (Light Fidelity), or wireless connectivity into new product lines. --- ### 9. **Cost Management** - **Economies of Scale**: Increase production volumes to lower per-unit costs while maintaining high quality. - **Process Optimization**: Regularly review and refine manufacturing processes to maximize throughput and minimize expenses. - **Total Cost of Ownership (TCO)**: Evaluate not just upfront costs but also long-term operational savings when investing in new equipment or systems. --- ### 10. **Strong Leadership and Strategic Vision** - **Clear Goals**: Set measurable objectives for manufacturing excellence, such as reducing defect rates by X% or shortening cycle times by Y%. - **Empowered Teams**: Empower managers and workers with decision-making authority to respond swiftly to challenges and opportunities. - **Long-Term Commitment**: Recognize that achieving manufacturing excellence is an ongoing journey rather than a one-time achievement. --- By focusing on these strategies, companies involved in the manufacture of lighting equipment can achieve **world-class standards** in their operations. This not only enhances their reputation in the marketplace but also positions them as leaders in innovation, sustainability, and customer satisfaction.

- 18,000㎡ factory with 400-500 skilled staff specializing in Laser & LED Stage Lighting.

- 100,000-grade purification workshop ensures static and dust prevention.

- One-stop production line, covering laser diodes, stepper motors, scanners, and housings.

- Advanced laboratory dedicated to rigorous testing for higher and more stable quality.

Comprehensive Support, Exceptional Service

- Expert Technical Team offering installation guidance and rapid troubleshooting to ensure smooth system operation.

- Innovative Technology: Integration of wash, zoom, and pixel mapping in new product developments.

- 24/7 Customer Support: Prompt and efficient assistance, no matter when the product was purchased.

- Long-term Service Commitment: Continuous technical support and fast issue resolution for a worry-free experience.

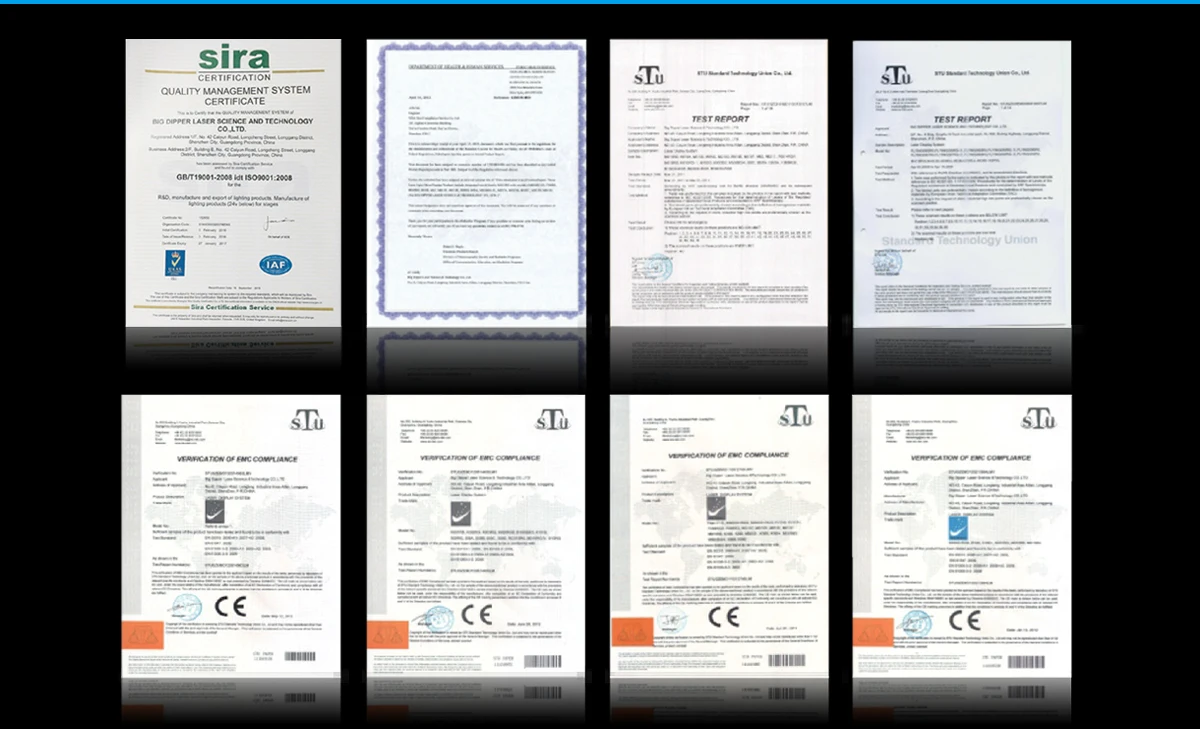

Global Certification, Trusted Quality

- Certified under the ISO 9000 international quality system.

- Products meet global standards with CE, ROHS, PSE, and FDA certifications.

- Compliance with diverse regulations across different countries.

1,500,00

1.5 million units sold annually, 21 years of experience – Betopper, trusted by customers worldwide.

Contact Us

You can contact us through the contact form below.

service@betopperdj.com