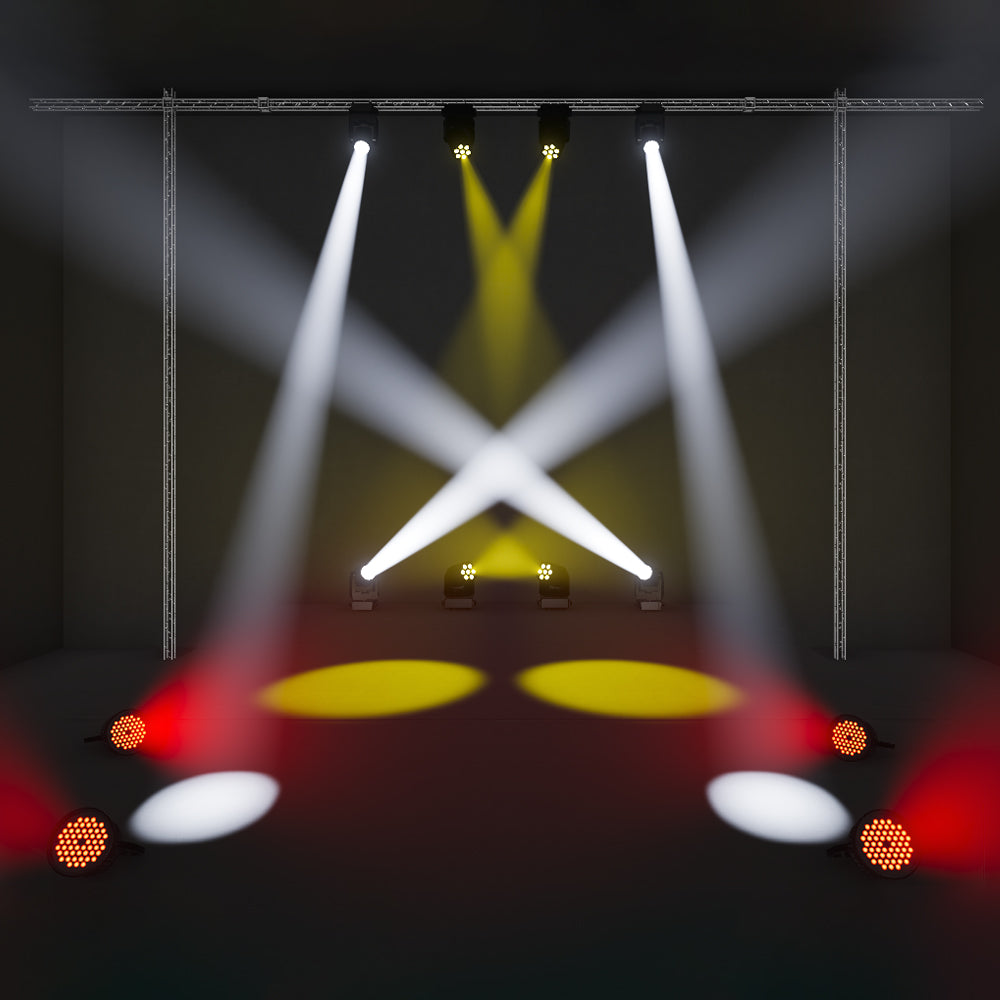

Moving head lights are essential tools in stage lighting, offering even light distribution and precise positioning capabilities widely used in various events. To ensure their long-term stable operation, daily maintenance is crucial. This article details how to maintain your moving head lights to ensure they continue to provide excellent lighting performance for years to come.

1. Overview of Moving Head Lights

Moving head lights are fixtures capable of moving in multiple directions (vertical, horizontal, and diagonal). They are commonly used in concerts, performances, dance floors, and entertainment venues. Due to their complex design and demanding working environments, moving head lights can have a high failure rate, making regular maintenance essential. A malfunctioning light can not only impact the quality of the performance but also pose safety risks.

2. Importance of Maintenance

Regular maintenance of moving head lights not only extends their lifespan but also ensures stable and safe operation during performances. Neglecting maintenance can lead to failures, resulting in costly repairs and potential performance incidents. Therefore, routine upkeep is necessary to guarantee the reliable functioning of the fixtures.

3. How to Keep Fixtures in Good Condition

3.1 Cleaning the Fixtures

- External Cleaning: Use a soft cloth or damp paper towel to regularly wipe the fixture's exterior. Avoid using corrosive cleaning agents, especially on coated and optical lens parts, to prevent scratches or damage.

- Lens and Optical Components: Pay special attention to cleaning the lens to maintain its clarity. Regularly check the integrity of the coatings and optical lenses, and perform professional cleaning if necessary.

3.2 Dust Removal

Post-Performance Cleaning: After each performance, use an air gun or compressed air to remove dust and debris from the lens and various crevices, preventing dust accumulation that can diminish light output.

3.3 Proper Storage

3.4 Internal Inspection

- Regular Checks: Periodically open the fixture's plastic cover to inspect the internal components. Key inspection points include:

- Wiring: Ensure all wires are securely connected and free from damage.

- Light Path Clearance: Check for dirt or debris obstructing the light path and clean if necessary.

- Circuit Boards and Connectors: Verify that the printed circuit board and connectors are intact and functioning properly.

- Lamp and Reflector: Regularly check the lamp and reflector for functionality.

-

Motor and Other Components: Inspect the motor and moving parts for smooth operation.

4. Common Issues and Solutions

4.1 No Response when Powered On

- Power Check: Ensure the power source is operational, and the power cable is securely connected.

- Fuse Check: Inspect the fixture's fuse for any damage and replace if necessary.

- Switching Power Supply: Confirm that the fixture's switching power supply is outputting voltage.

4.2 Lamp Not Lighting

- Lamp Quality: Check the lamp for any defects, including burnt contact points.

- Ignition Voltage: Measure the ignition voltage on the main board, which should typically be between 10-12 volts.

- PFC Output Check: Verify that the PFC output (input to the igniter) has an AC voltage output of around 380V.

4.3 Lamp Automatically Turning Off

- Cooling System: Check if the cooling system is functioning correctly, as overheating can cause the temperature switch to trip.

- Lamp Lifespan: Determine if the lamp has reached the end of its lifespan. Signs include a white surface with a black interior.

4.4 Gobo Wheel and Color Wheel Jamming

- Mechanical Inspection: Investigate if the gobo wheel or color wheel is jammed due to mechanical issues. Ensure screws and springs are secure.

- Motor and Channel Check: Ensure motor connections are intact and no damage to the channel chips.

5. Additional Usage Considerations

- Handle with Care: Always handle fixtures carefully to avoid collisions or drops that could cause damage.

- Avoid Harsh Environments: Try not to use lights in sandy or dusty conditions; maintain cleanliness regularly.

- Post-Show Cooling: After a performance, extinguish the lamp using the control console, allowing the fixture to run for a while to cool down.

- Transport Protection: After a touring event, store fixtures in specialized flight cases to protect against moisture, shock, and dust.

6. Importance of Regular Maintenance

To maintain optimal performance, regularly cleaning lenses and lubricating gears and suspension components is essential. It’s recommended to replace motor surrounding brass bushings with softer materials for more even wear, extending lifespan. Qualified technicians should conduct regular professional maintenance to ensure your fixtures are always in peak working condition.

By adhering to regular maintenance and professional upkeep, your moving head lights will continue to deliver high-quality lighting performance. Understanding these maintenance practices will not only prolong the lifespan of your fixtures but also enhance the overall quality and safety of your performances.

For more information, please follow our Betopper official website https://betopperdj.com/, or our official YouTube account https://www.youtube.com/@betopperofficial. Don't miss it!

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.